The Challenge

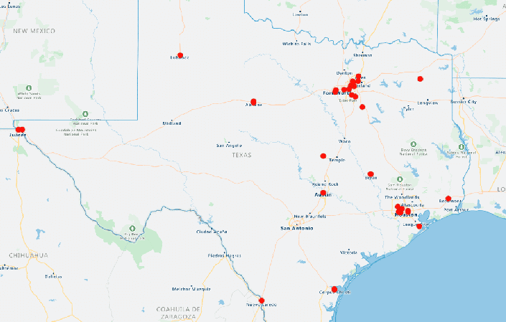

Lauren Concrete has an extensive service area across Central Texas with 26 plants. Each plant has different material costs associated with them for the same item. If two plants are equidistant from a specific job delivery location, one plant might be the more cost-effective option to service that job because the material costs are lower.

We wanted to know for each of our plants. What is the plant's low-cost service area? What is the geographic region around that plant? And whether that plant is the most cost-effective option to ship concrete. We wanted to take advantage of that. We also wanted to know the most costly delivery areas in central Texas. And which of our customers are in those areas.

Emily Jetmore

Business Analyst

The Solution

Lauren Concrete used eSpatial to process geographic data from each ticket they cut in the past year. For hundreds of thousands of records, they calculated the lowest possible material and delivery cost and what plant would provide that cost. They then uploaded all those records to eSpatial and used the style function to color-code points based on their low-cost delivery plant location. They drew polygons around those colored areas to mark what plants and low-cost service areas would be.

Findings

- Some plants had much more limited delivery areas, low-cost delivery areas than anticipated, and some more extensive.

- It really shook up the assumption that many people had that the 10 or 15 miles around a particular plant was best serviced by that plant. Sometimes it's a plant that is further away but has lower material costs.

- eSpatial was instrumental in turning complex data into easily digestible maps for leaders in their organization.

- By sharing color-coded maps with the leadership team and showing the optimal coverage areas by plant it helped convey a complicated idea to a much wider audience.

The Result

- Using eSpatial, they exported the data showing the difference between a plant's actual shipping cost and the comparison with a lower-cost plant

- They identified potential shipping cost savings of $1,700,000

- With that insight, they identified all the high delivery and material costs

Once Lauren Concrete identified a plant's low-cost service area, they could see what tickets had been shipped by a plant with higher material costs and identify how frequently that was happening.

They identified plants with limited service areas which helped them identify new material suppliers with lower material costs. That allowed Lauren Concrete to expand service areas. Without eSpatial, they failed to see the effects of the differential material costs. It helped them change how they think about the plant's territory and which plant will be the most cost-effective to ship to a particular geographic point.

Siemens used eSpatial to simplify decision-making on future new sites

LivaNova simplified territory alignment and visualization

TKG used eSpatial to help clients increase revenue

NAS cut sales reporting time by a month

Engel & Völkers create territories 32x faster

Seco achieved a higher level of customer engagement